What are heirloom juices?

Emergence of hereditary juices

Farmyard saps is a collective name for industrial waste water that originates (1) during the direct run-off of pressurised saps and leachate water from the yard/company premises; (2) as soon as rainwater on the yard/company premises comes into contact with organic material such as feed (residues), manure (residues), organic biological waste (OBA), pressurised saps and leachate water or (3) during cleaning and rinsing activities. The entirety of these farmyard juices should be considered as farm waste water that may not be discharged (untreated) unless explicitly authorised in the applicable standards framework.

Percolate water is a term for rainwater that seeps into the storage of organic material, thus causing the leaching of nutrients from the stored material.

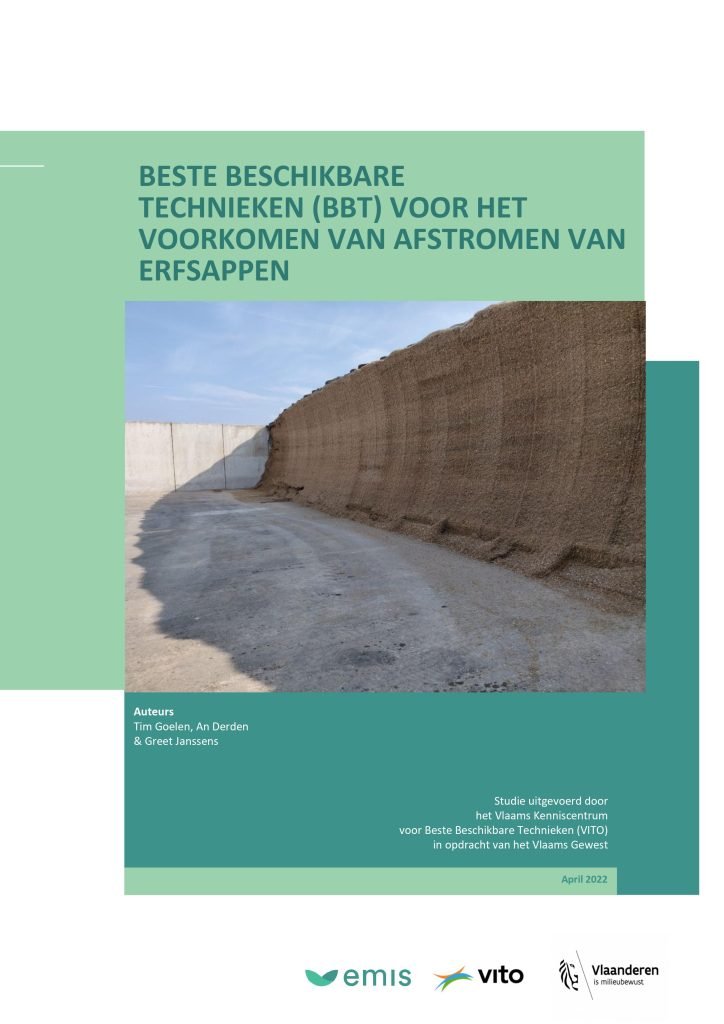

Within the term of legacy juices, there are also silosaps. Silosaps are legacy juices that can be formed when storing organic material such as feed and energy crops and/or biomass (residual) streams. These silosaps can be further divided into 3 categories.

- Press juices: Juices released during compacting, storage and preservation of organic material. The amount of press juices is mainly determined by the conditions at ensiling and the presence of scalding during storage.

- Percolate water: rainwater that seeps into the storage of organic material and thus ensures the leaching of nutrients from the stored material.

- Contaminated run-off water: stormwater runoff from surfaces contaminated with organic matter.

Many farms also have rinsing and cleaning water. This occurs when rinsing or cleaning machinery, paving, milking plant, ... A collection facility is also needed for these water flows.

Manure juices also belong to the set of yard juices. Manure juices are juices released from (mixtures of litter and) manure, for example at the level of the solid manure storage or the calf pens.

Measures

Avoiding yard sap runoff starts with preventive measures. In short, it starts with good agricultural practices. In practice, numerous measures can be applied.

Farmyard paving

A clean yard is not only pleasant to work in, it also immediately gives a positive image of the farm. Therefore, make sure the yard is swept at regular intervals. Maintain the yard. A well-maintained yard and well-maintained feed stores not only work pleasantly, but are also easier to keep clean. Repair subsidence, seal seams and cracks properly and empty sumps and gutters at regular intervals.

Create a logical layout of the yard. Make sure the distance between the stable and a storage is not too long.

Divide your yard into a 'clean' and 'dirty' section and also ensure that the routes of each section do not cross each other. Ensure that polluted rainwater cannot run off into surface water, and make the 'working' part, also known as the dirty part, as small as possible. Collect press juices, manure juices and leachate water and use it, for example, to dilute manure. On the farm site, the separation of clean rainwater and dirty water flows is often not sufficiently taken into account when adapting and designing the farm site. Farmers can already achieve a lot preventively by being vigilant for feed and manure residues, keeping the yard sweep-clean and avoiding run-off from dirty water flows.

Feed storage

When storing fodder, take measures to reduce pollution from stormwater runoff. Pit therefore always in under good conditions. Thus, press juices are kept to a minimum. This can be done by:

- to pit under good weather conditions (dry weather),

- ensilage at the right harvest time (%DS),

- not to pit higher or further than the walls

- cover the storage properly (air and watertight) and

- consider an absorbent underlayer (such as straw) if wet ensilage is used. This will absorb much of the baling juices and prevent them from flowing off.

Also consider a separate disposal in the silage storage. Various versions of this are available in which clean rainwater is separated from press juice/percolate water. Depending on the system and the position of the feed, the farmer himself decides which drains are open and which are closed. It is essential for this to work properly, however, that the plate is kept clean at all times.

Avoid spill when transporting feed as much as possible. If a spillage does occur, clean it up immediately. Make the transport distance from the feed store to the barn as short as possible.

If there is a First Flush is present on the farm, it should be correctly adjusted. Also ensure that it is emptied at regular intervals to ensure capacity. Again, the precaution of a wipe-clean silage tray for proper operation applies.

Solid manure storage

The next compartment to consider is solid manure storage. Make sure solid manure storage is large enough to allow for long-term storage. Consider the legislation (3 manure-proof walls and a manure-proof substrate). Also ensure that a collection for the manure juices is provided, preferably at the rear wall, so that as little juices as possible can flow away from the collection. To prevent rainwater contamination, consider installing solid manure storage canopy.

Housing of young stock (calf pen,...)

Ensure that housing for calves is arranged in such a way that collection is provided for any manure juices from calf pens and calf entrances. If the calf pens are in the barn, the manure can usually be collected in the manure pit. If they are outside, separate collection is often required. Here, an additional option may be to place the calf pens under a canopy to be placed, reducing rainwater pollution. The clean rainwater can then be collected or diverted separately.

Koepad

Make sure a cow path is as short as possible and that no run-off can occur. Also make the cow path at regular intervals clean, especially when precipitation is predicted. When considering a new cow path, lay it so that vehicles are not driven on the soiled cow path. It is also important that the pavement is easy to keep clean. There may be street gullies be provided at the cow path just behind the stable with an outlet to the manure pit. Outside the grazing season, these gullies can be closed if the cow path is clean.

Cleaning site agricultural machinery (without crop protection)

Clean implements at a designated place with a sump. Also ensure that this cleaning place is sufficiently large for the machines used. The cleaning area should be provided with a sludge collection and a KWS - separator (oil or hydrocarbon separator)

Small changes with big effects

Avoiding pollution can often be quite simple. Some questions you can ask yourself:

- Have all pavements been swept clean?

- Are no drains or drains clogged?

- Are the feed silos swept clean? Is there a risk of run-off contaminated rainwater?

- Are the silo walls free of cracks and fissures?

- When using a First - Flush:

- Is it properly adjusted?

- Is it emptied in a timely manner?

- Is rinsing and cleaning water collected correctly?

- Are all manure juices collected?

- Are the calf huts in a suitable place with shelter?

- Is my cow pad clean?

- Is rainwater from my roofs collected or diverted separately so that it does not become polluted?

BAT - study (Best Available Techniques)

By 2022, a BAT - study will have been completed for Flemish farms and cover fermentation plants to prevent run-off of inherited juices and emissions to surface water and soil.

Besides mapping the farmyard sap that may run off onto the farmyard or premises, the objective of this study was to evaluate measures that can prevent or limit direct runoff of farmyard sap and contamination of rainwater as much as possible, thereby minimising the risk of environmental pollution of water and soil. BATs and environmentally friendly techniques were identified on the basis of available information including in the literature, in the context of projects and through company visits. The BAT selection in this study was made in close consultation with industry representatives and specialists from the administrations. The study was also submitted to an external lecturer for critical review.

This blog is in the context of following projects

Demonstration project BESS

Leader project Water quality, an integrated approach